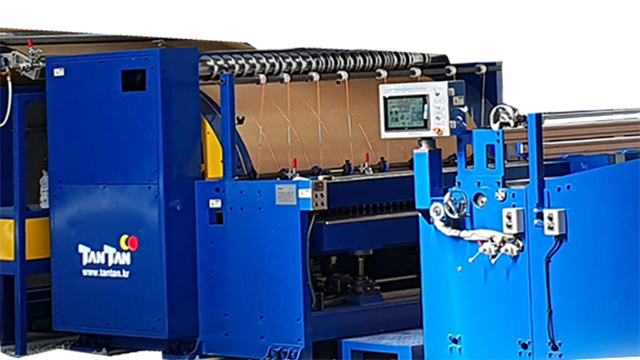

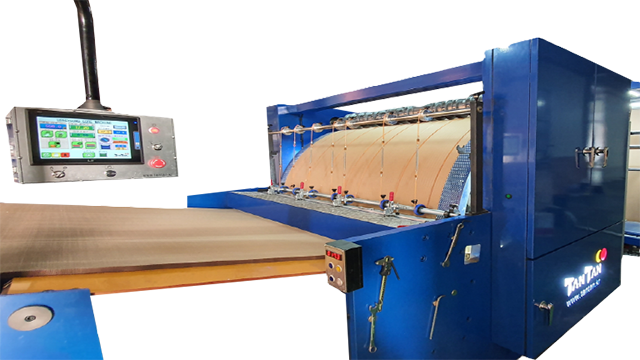

PRODUCT • CORE MACHINE

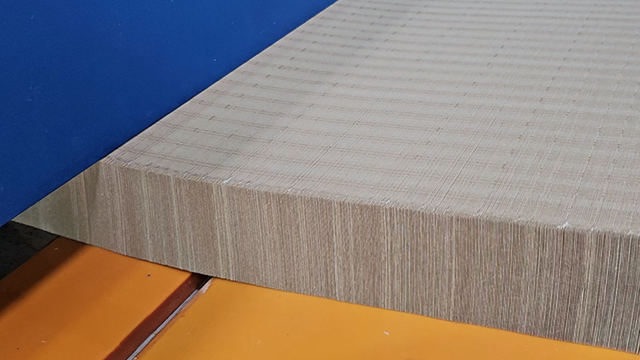

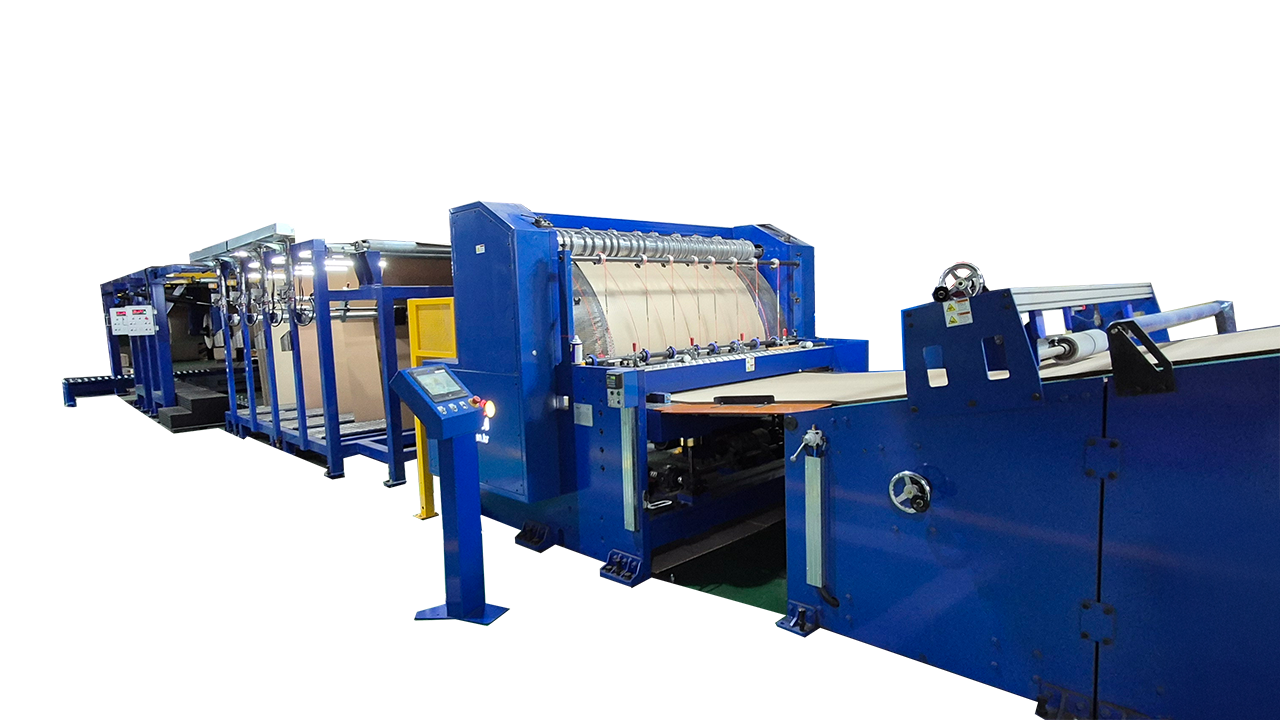

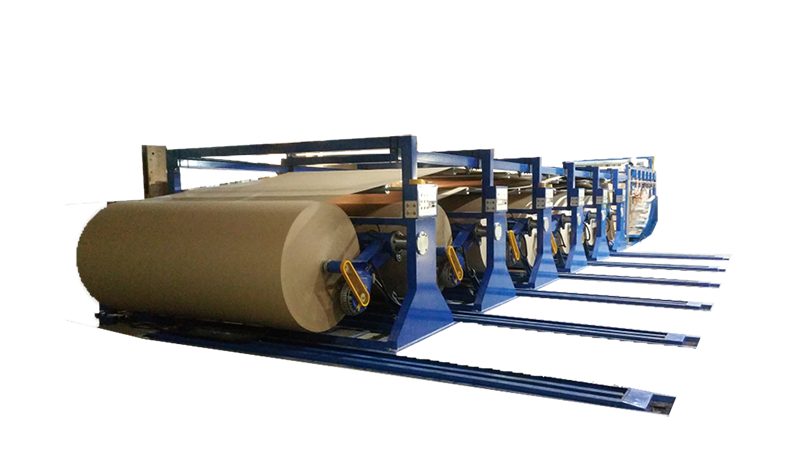

PAPER HONEYCOMB CORE MACHINE

Standard

Jumbo

Mini

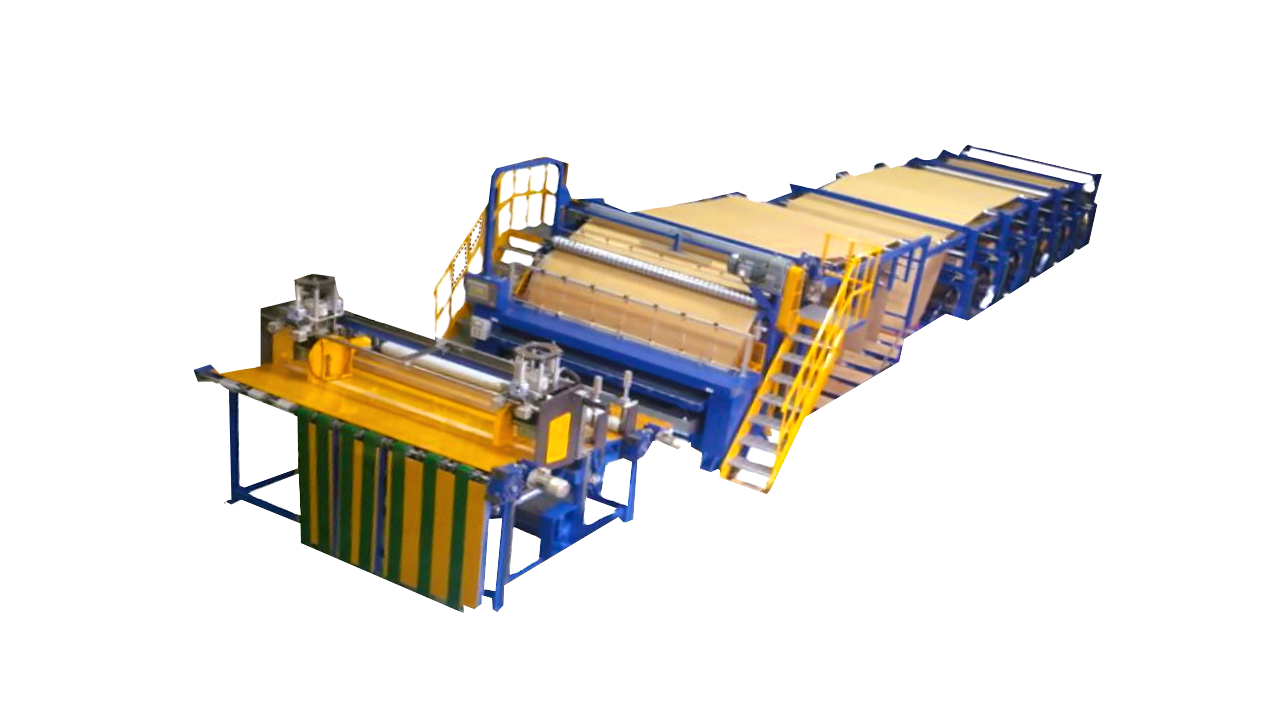

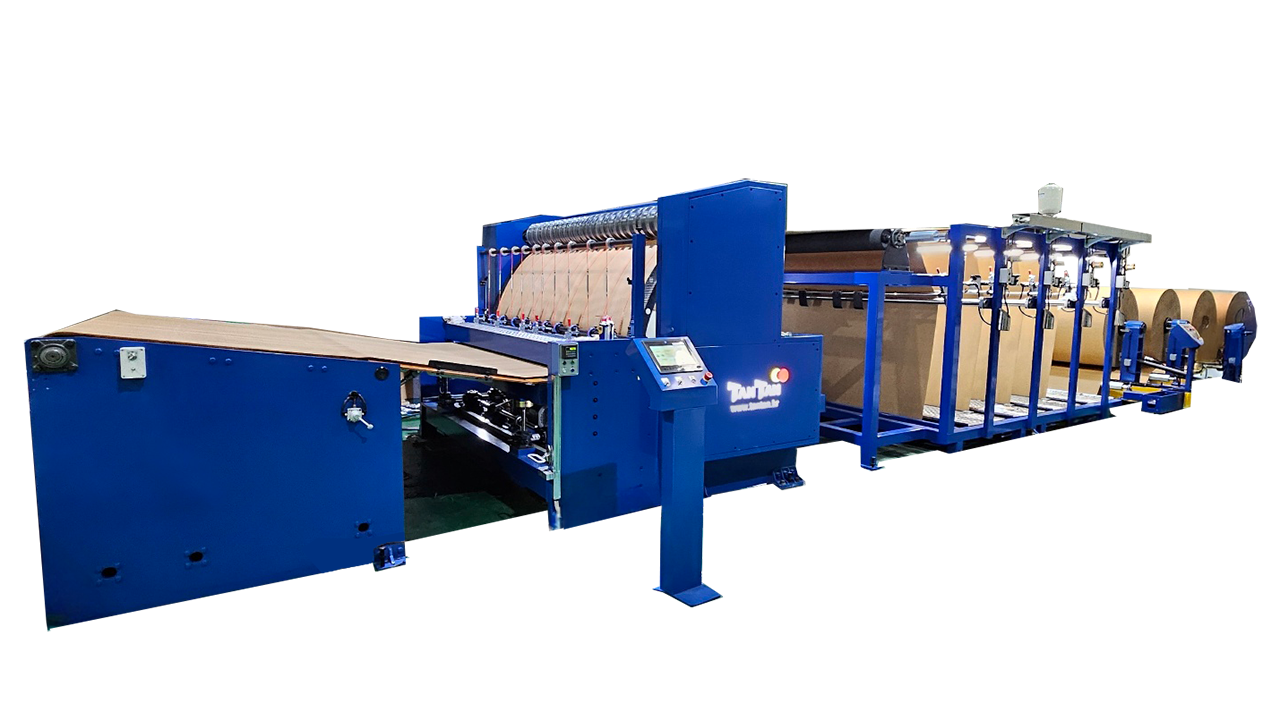

Standard & Jumbo

HCM-1800/2100/2600/2800 (70"/82"/102"/110")

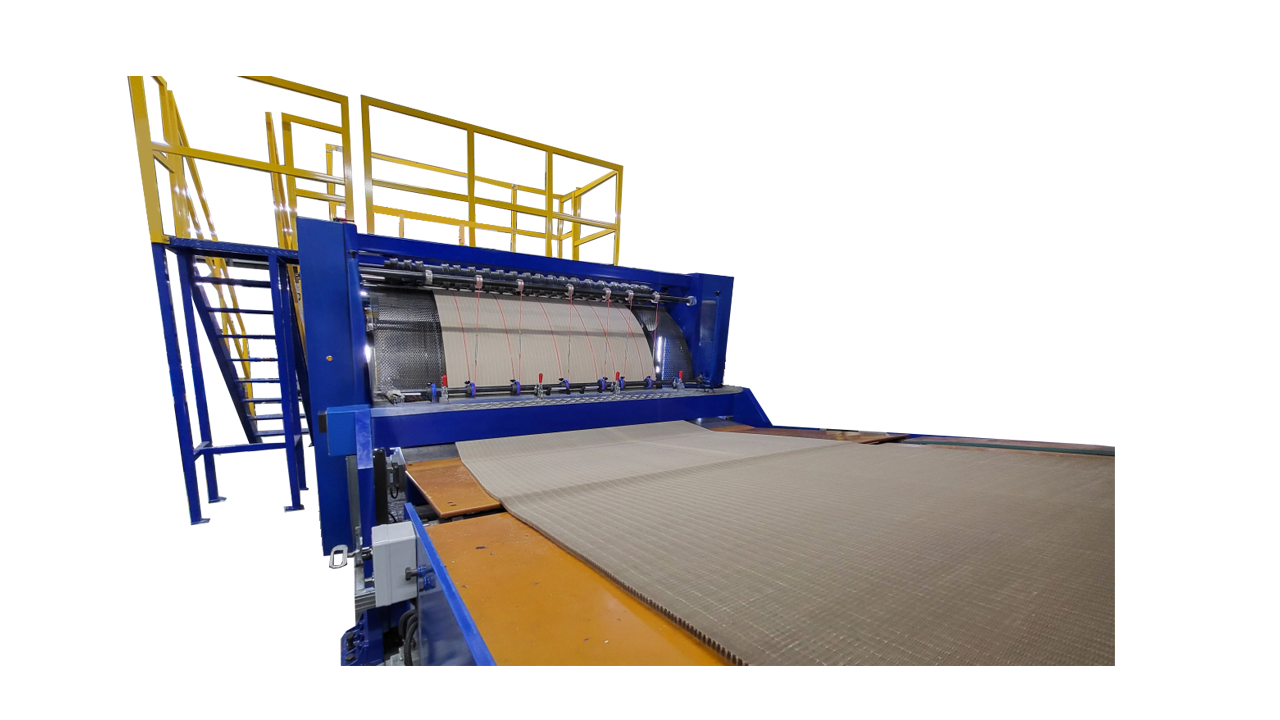

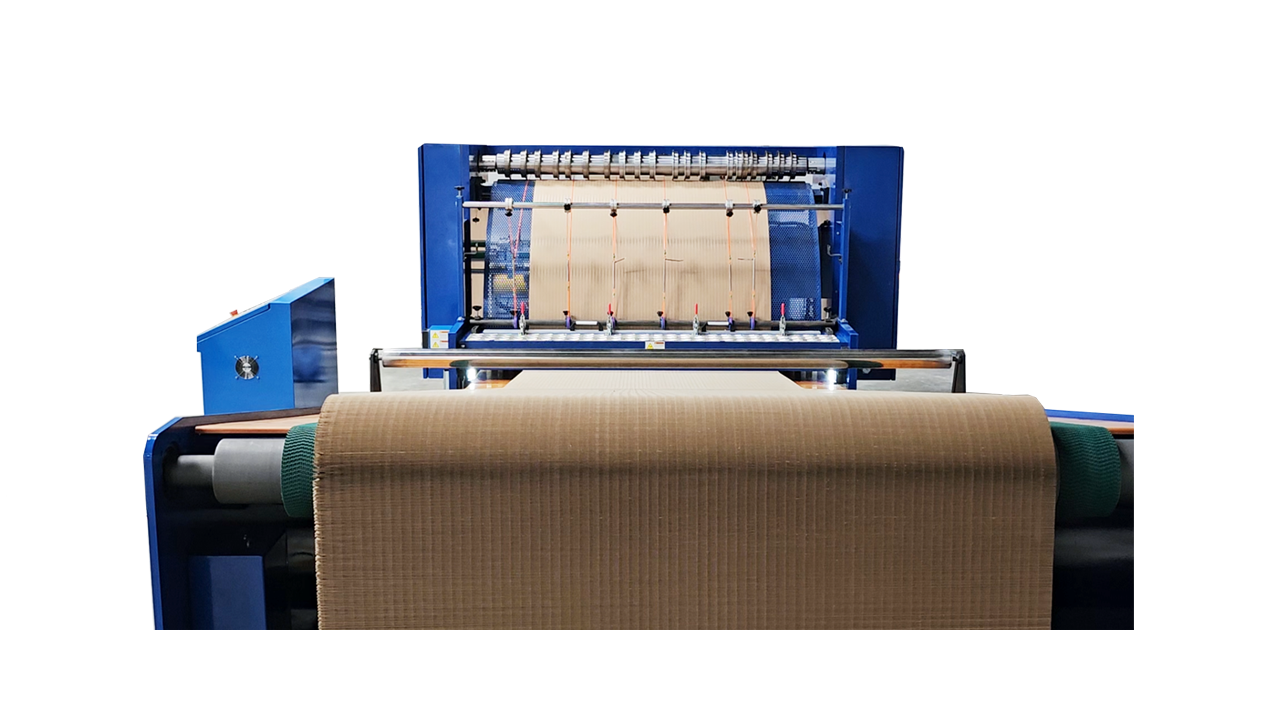

[Process] ..Feeding >> Gluing >> Cutting >> Delivering

General Specifications

- Working width : 1800/2100/2600/2800mm (70″/82″/102″/110″)

- Paper : Kraft paper, OCC Recycled paper in roll, 150-400gsm

- Adhesive : PVA / Starch

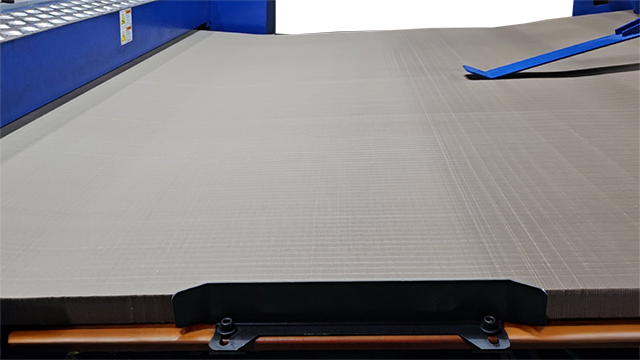

- Cell size: 8-100mm (0.31-3.94″)

- Wide range of options: Cell specifications modifications, Notching (U-Grooving), Core Slitting, Pre-Printing etc…

Major Features

- Endless core production

- High speed performance

- Vibration absorption system

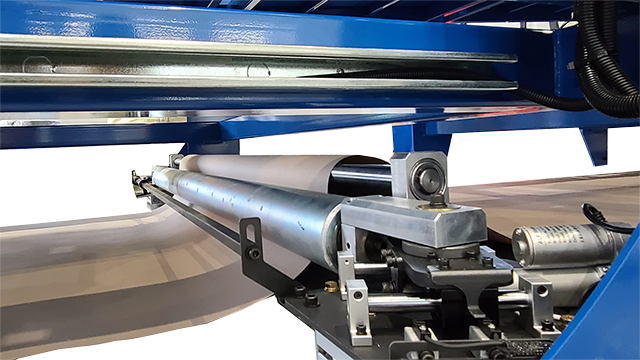

- Auto tension system

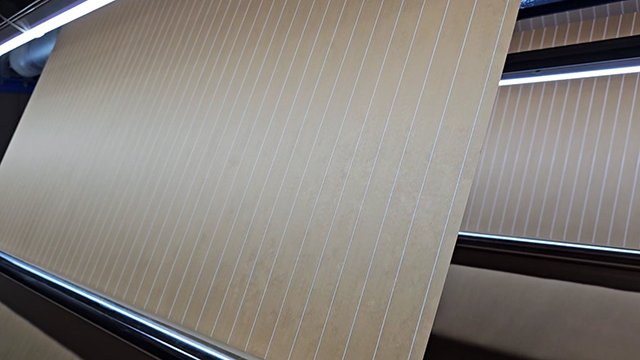

- Gluing unit with flow metering

- Edge positioning

- Custom options available to meet special requirements

Major Benefits

- Increase the efficiency of the critical daily operating task

- Reducing manpower, cost and time required each day..

- Ensuring smooth production start ups each morning

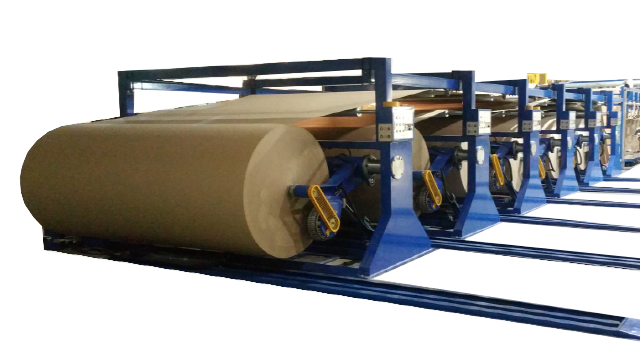

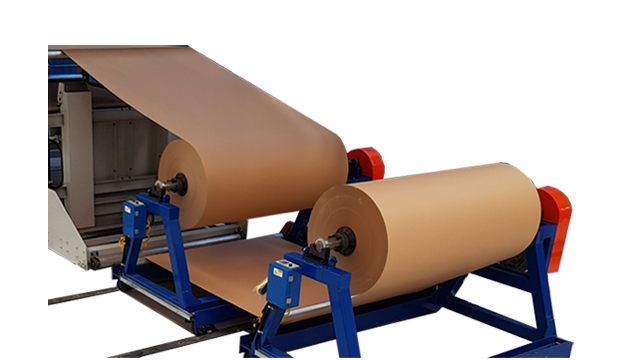

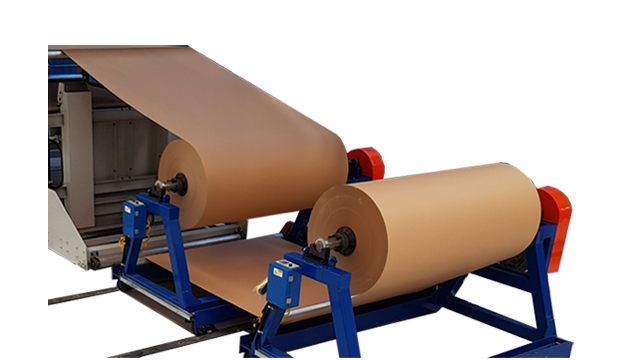

1. Paper Roll Feeding

2. Tension Control

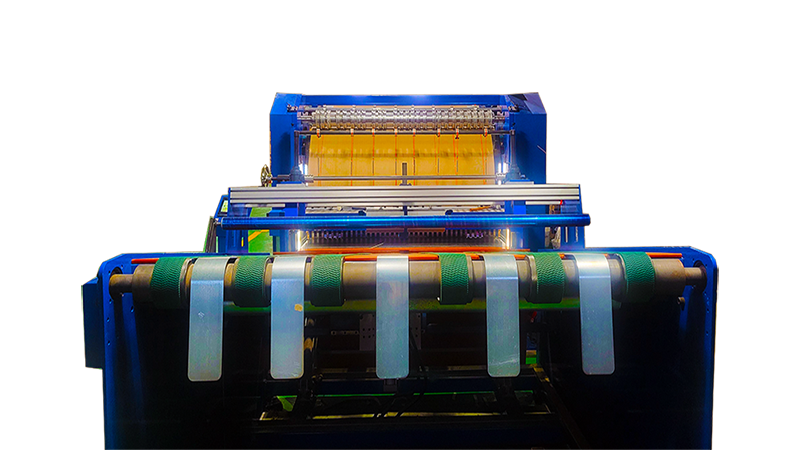

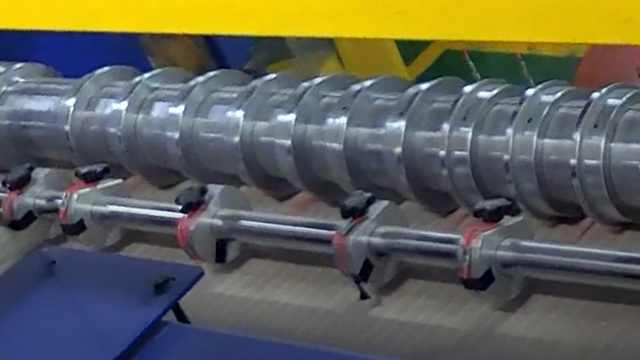

3. Gluing

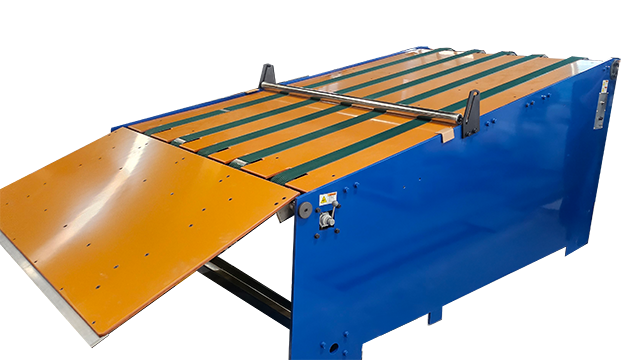

4. Cutting

5. Notching

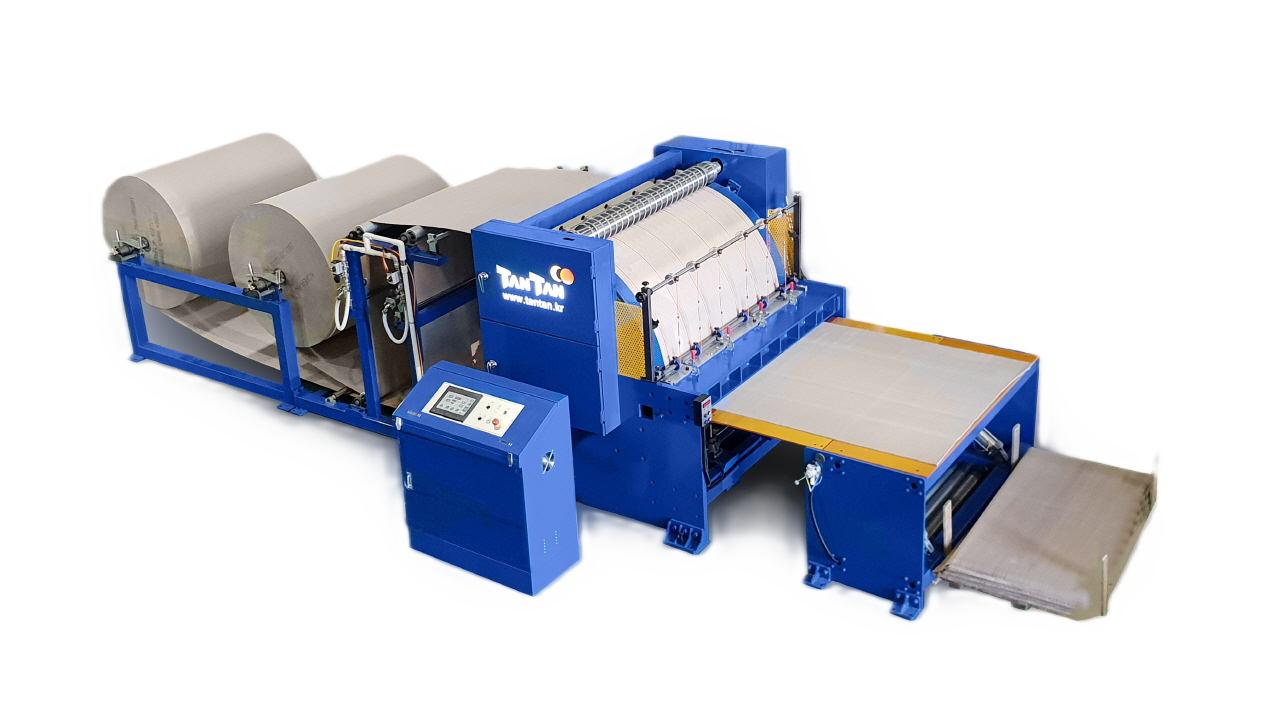

Mini, Cost-Value

HCM-1600 (62")

[Process] ..Feeding >> Gluing >> Cutting >> Delivering

Main Specifications

- Working width : 1600mm (62″)

- Paper : Kraft paper, OCC Recycled paper in roll, 150-400gsm

- Adhesive : PVA / Starch

- Cell size: 6-100mm (0.24-3.94″)

Major Features

- Endless core production

- Compact and simple structure

- Useful for small cell thickness (height)

Major Benefits

- Operator friendly

- Designer for small and medium producer

- Simple maintenance

- Minimized loss rate for beginner.

0. Video Display

1. Paper Roll Feeding

2. Gluing

3. Cutting