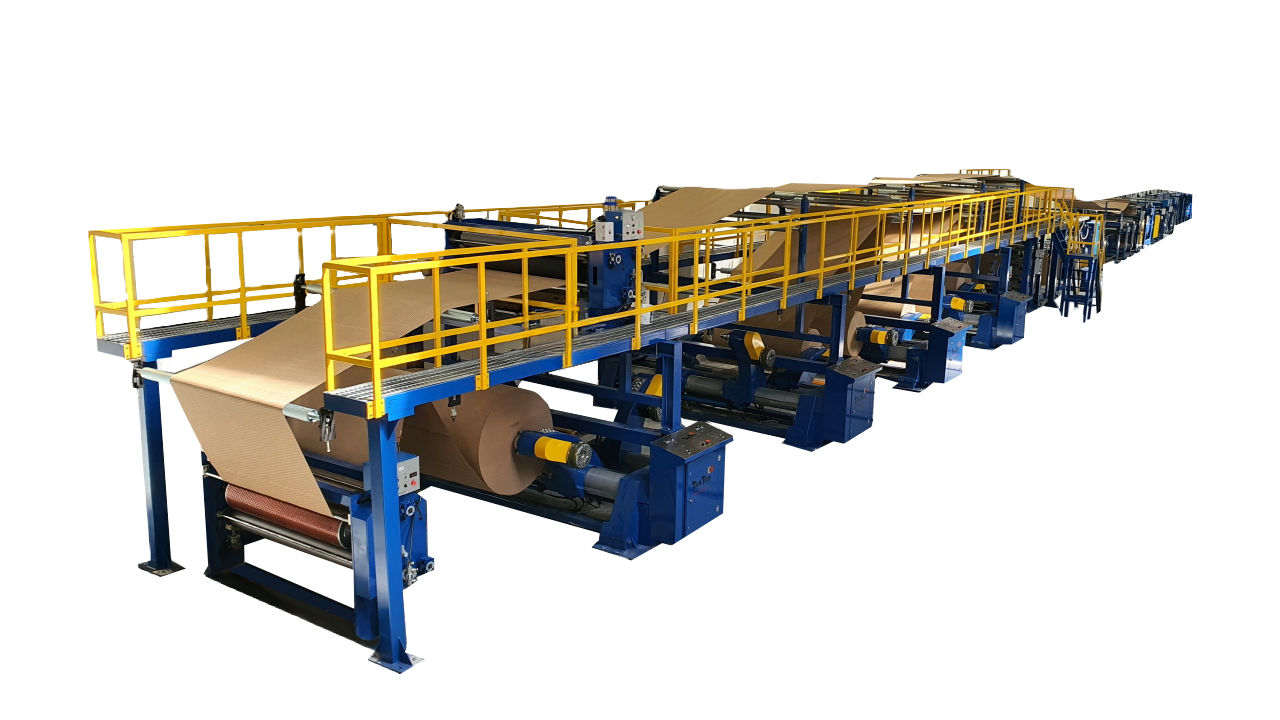

PRODUCT • CORE & BOARD MACHINE

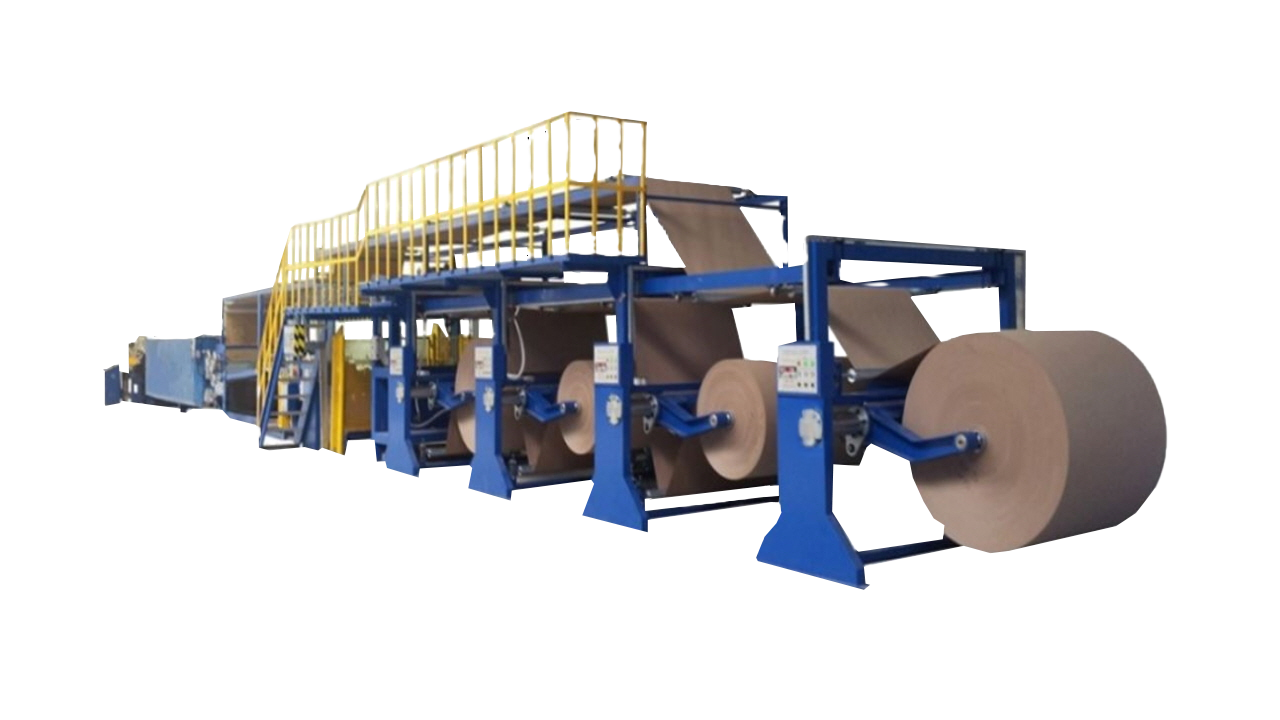

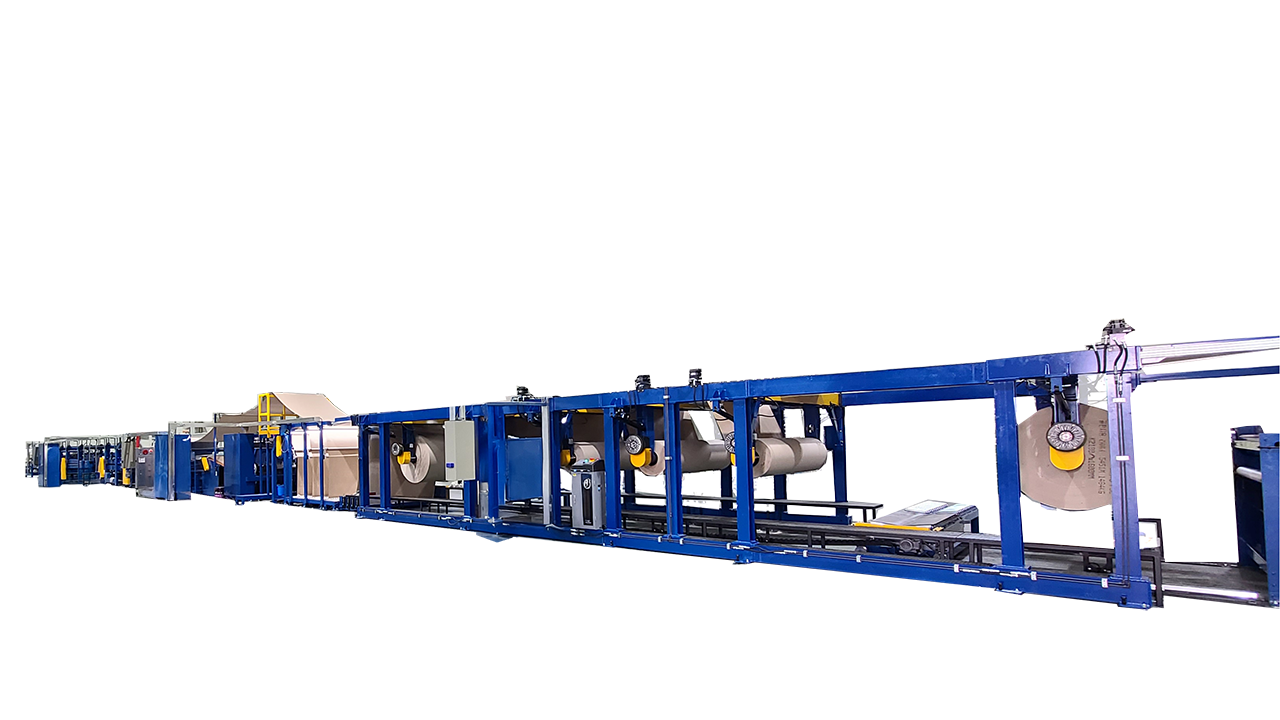

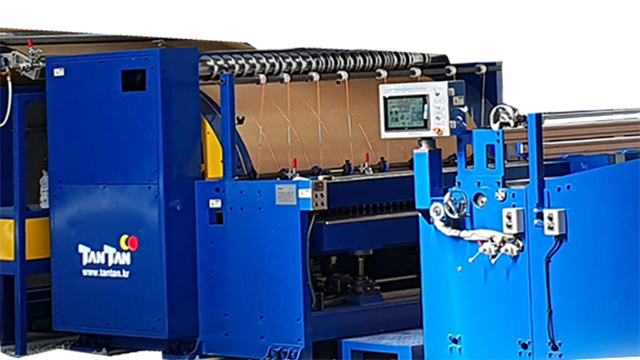

PAPER HONEYCOMB CORE & BOARD MACHINE (IN-LINE)

COMBO-2100(82″) / 2300(90″) / 2600(102″) / 2800(110″)

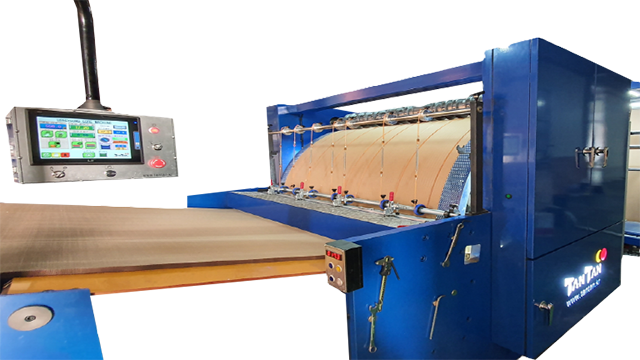

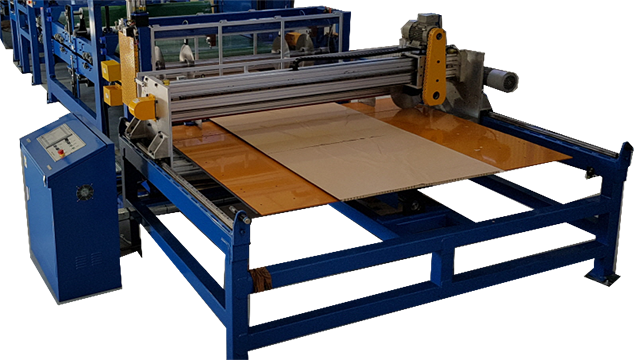

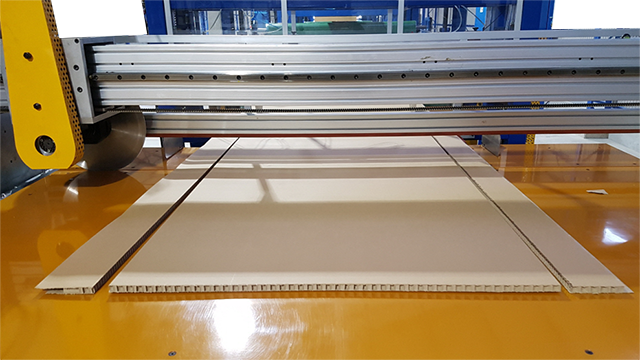

[Process] Feeding ⇒ Gluing ⇒ Cutting ⇒ Notching ⇒ Transferring ⇒ Expanding ⇒ Gluing ⇒ Heating ⇒ Laminating ⇒ Slitting ⇒ Board Cutting

General Specifications

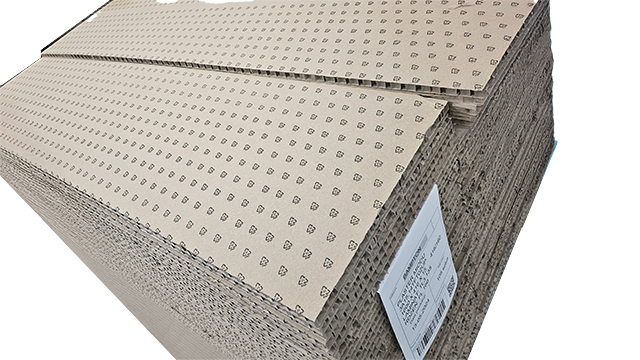

- Working width : [Core] 1800/2100/2600/2800mm (70″/82″/102″/110″) [Board] 1600/1800/2300mm (62″/70″/90″)

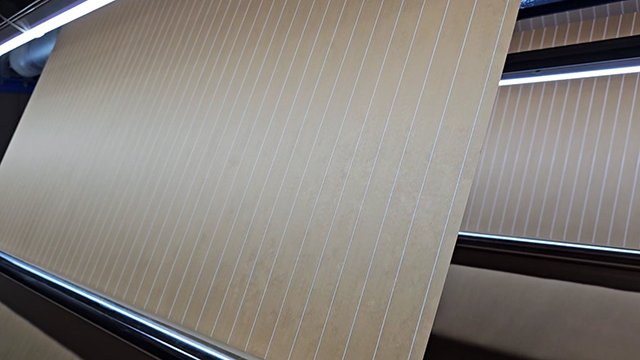

- Paper : Kraft paper, OCC Recycled paper in roll, 150-400gsm

- Adhesive : PVA / Starch

- Cell size: 8-100mm (0.31-3.94″)

- Board thickness : 8-100mm (0.31-3.93″)

- Glue metering system

- Quick glue cleaning system

- Energy saving heating

- Board cutting up to 300mm (11.8”)

- Wide range of options: Cell specifications modifications, Notching (U-Grooving), Core Slitting, Pre-Printing, Board thickness modifications, Printer, Varnisher(Coater), Board Trimmer, Core Pre-Loader.. etc…

Major Features

- In-line core & board production

- Endless core production

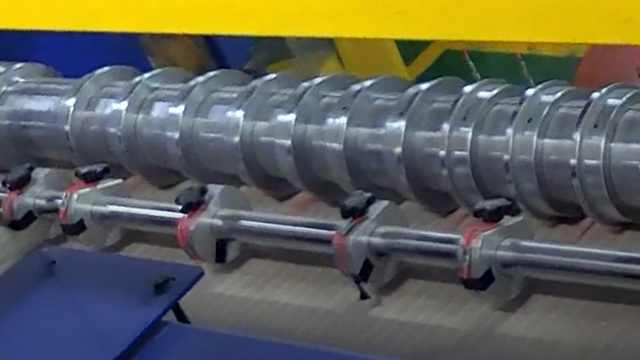

- Vibration absorption system

- Gluing unit with flow metering

- Edge positioning

- Quick glue cleaning system

- Energy saving heating

- Min.Board cutting up to 300mm (11.8”)

- Custom options available to meet special requirements

Major Benefits

- Increase the efficiency of the critical daily operating task

- Reducing manpower, cost and time required each day..

- Ensuring smooth production start ups each morning

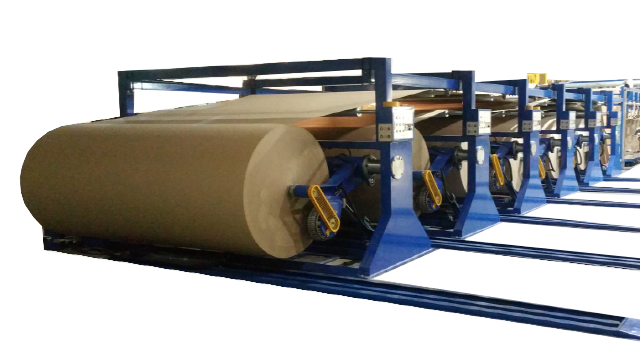

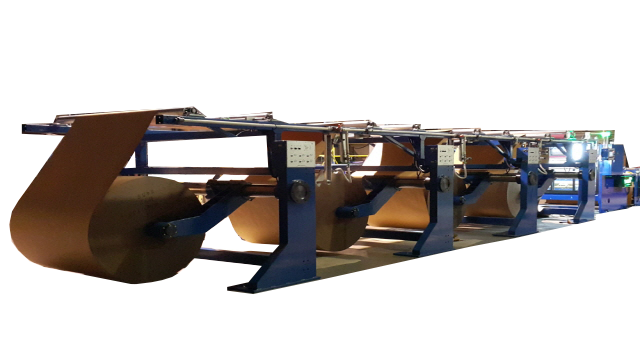

1. Roll Paper Feeding

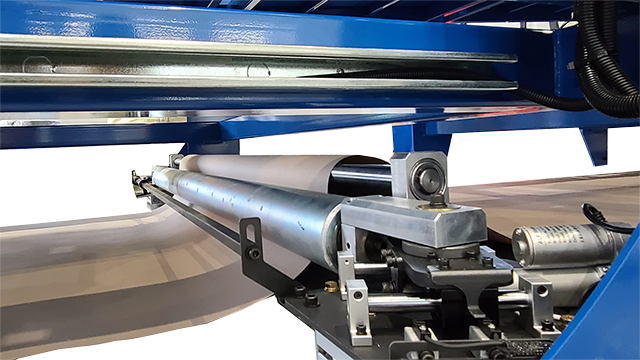

2. Tension Control

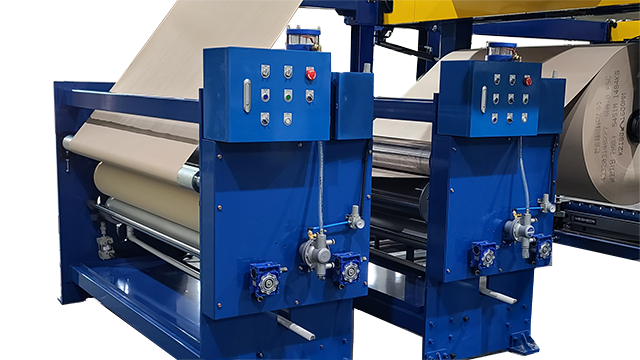

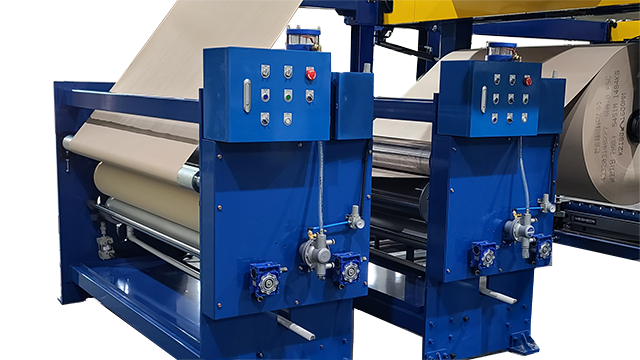

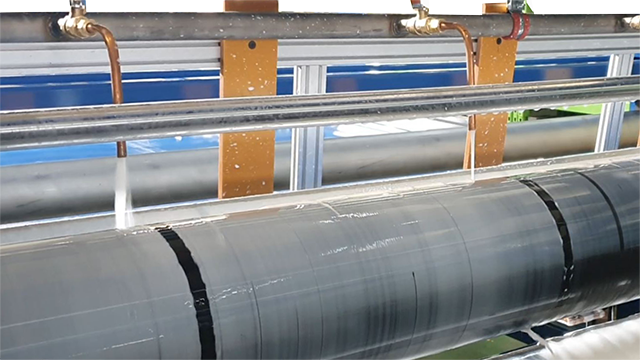

3. Gluing (Core Sec.)

4. Core Cutting

5. Notching

6. Transferring

.

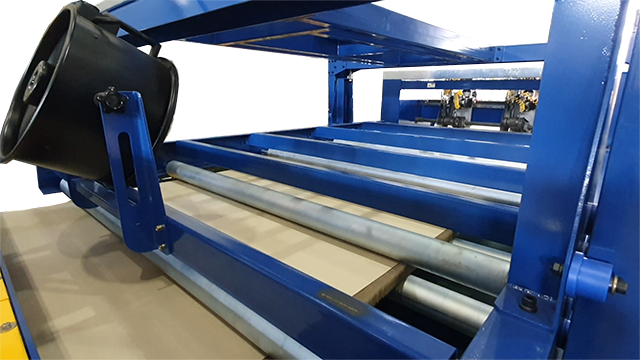

7. Core Feeding

8. Core Pre-Loading

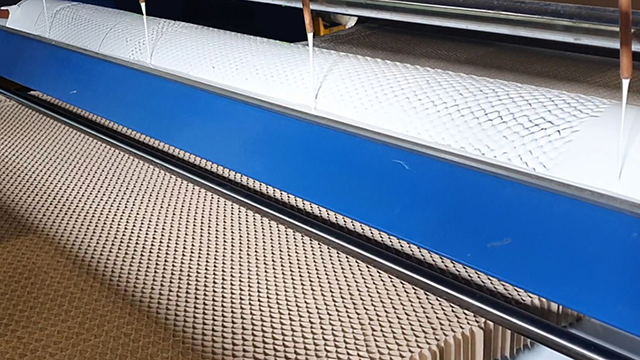

9. Core Expanding

10. Gluing

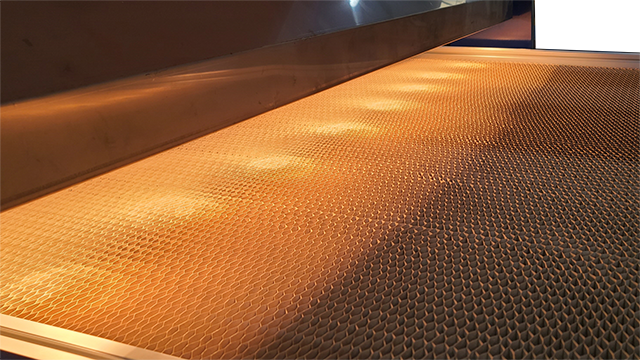

11. Chamber Heating

12. Plate Heating

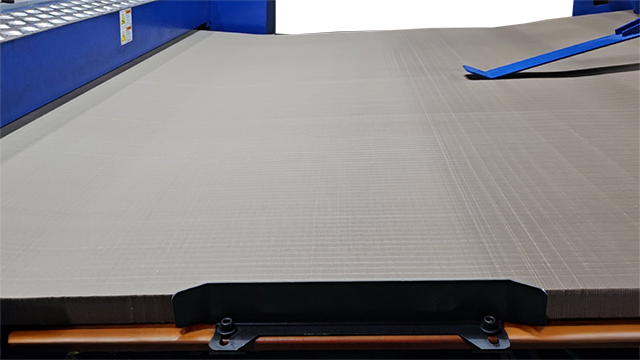

13. Belt Pressing

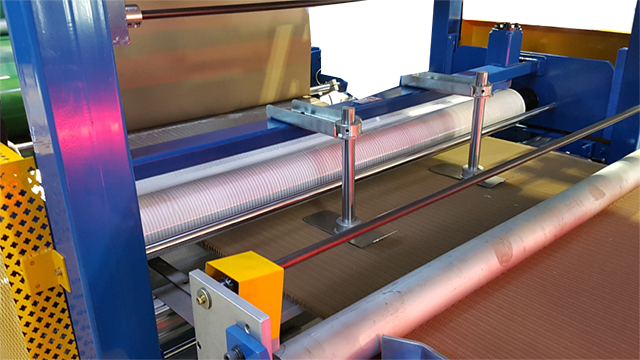

14. Roll Pressing

.

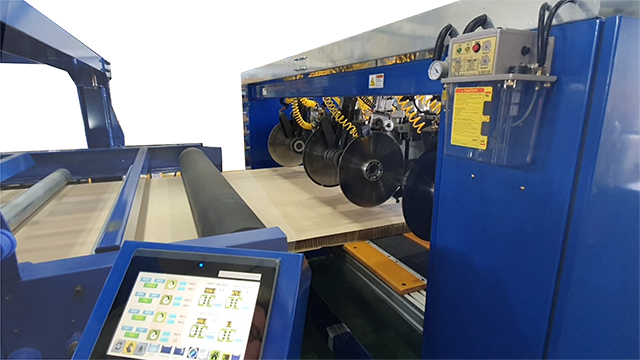

15. Board Sliting

16. Trimming

17. Board Cutting

18. Printing

19. Coating